CONSULTING - ENGINEERING - FABRICATION

IGH’s Main products incl. related facilities

- Movable type converter 2-5 t for special alloys and steel foundries (Patented)

- Top blown oxygen lance folding type for small converters (Patented)

- AOD (Top and bottom) 3 t to 120 t

- LD (Top and bottom) 60 t – 150 t

n Reconstruction and Modernisation of the existing plants specially IOC (AOD) – Plants ( 3 – 120 t )

n Erection, supervision of erection and commissioning

n Process-know-how, training and technical assistance in our steel plants or at customers site

n Various plants, equipments and units for Foundries, Steel plants, Rolling mills, Chemical industries and Power plants

n Supply - Facilities:

n Metallurgical plants and equipments (already supplied)

n Transfer cars, ladle cars etc.

n Ladles ( 10 t – 180 t )

n Converter vessels ( 3 t – 120 t )

n Trunnion ring

n Oxygen lance

n Dust collection plants (dry basis)

n Mechanical parts already supplied to various customers in Germany

n Electric arc furnace (4 t - 160 t)

n Ladle furnace (100 t - 400 t)

n Vacuum plants (30 t - 250 t)

n Continuous casting plants ( Billets)

n Chemical industries and power plant industries

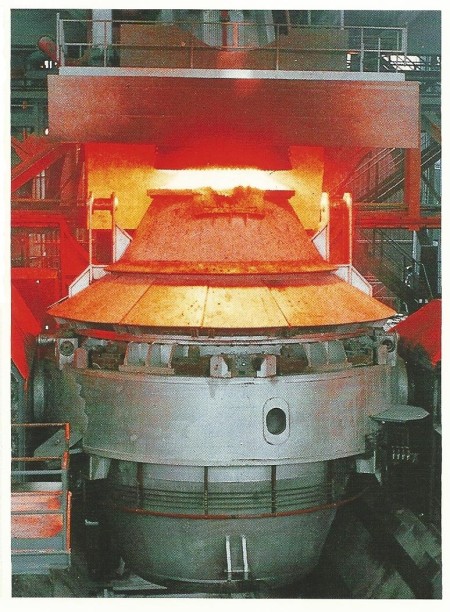

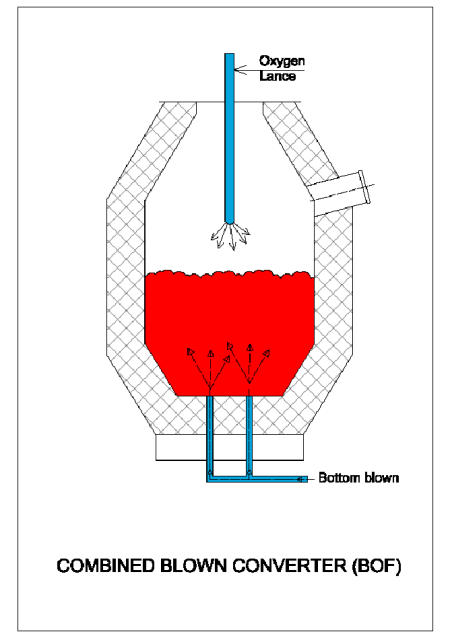

OXYGEN STEEL MAKING (BOF)

Till today maximum crude steel produced via oxygen blowing converter route and this process route already established throughout the world. The rapid improvement of blowing technique (top & bottom) also achieved world recognition with the following advantages:

- Improved target accuracy of chemical composition and temperature

- Reduced tap-to-tap cycle time less than 35 mins

- Less reblow of the melt

- Increased metallic yield

- Reduction Fe-content of converter slag

Today’s oxygen blowing steel plant consists of following bays:

- Charging bay

- BOF-Converter bay

- Ladle bay

- Casting bay

The programmable logic control system (PLC) is used to carry out direct process sequence via Level I and Level II operation to determine C-content, temperature and target analysis economically.

The main fabrication and supply of IGH for BOF converter are as follows:

- Converter vessel

- Trunnion ring with shafts

- Trunnion bearings

- Converter tilt drive unit

- Oxygen top lance

- Bottom blowing facilities

- Flux and alloy addition system

- Exhaust gas cooling and cleaning

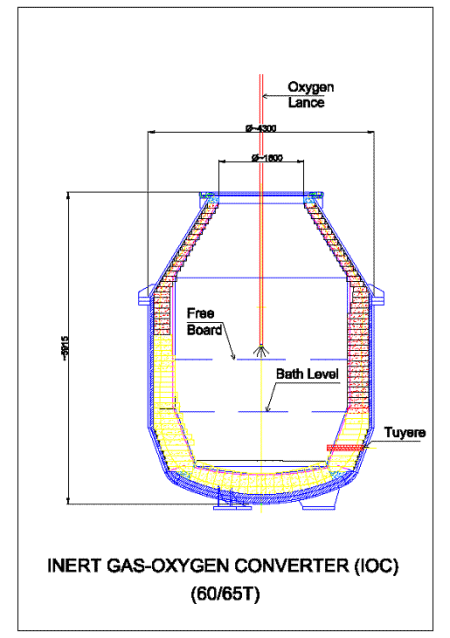

INERT GAS OXYGEN CONVERTER (IOC)

The steel refining converter is a duplex or two stage process. The molten metal will be premelted in any premelting furnace and charged into a refractory lined converter. Exact calculated amount of process gas (Oxygen, Nitrogen and Argon) are blown through submerged tuyeres to achieve optimum thermodynamic and kinetic conditions to produce value added steel.

IOC 60/65T

UNDER OPERATION

GAS MIXING STATION

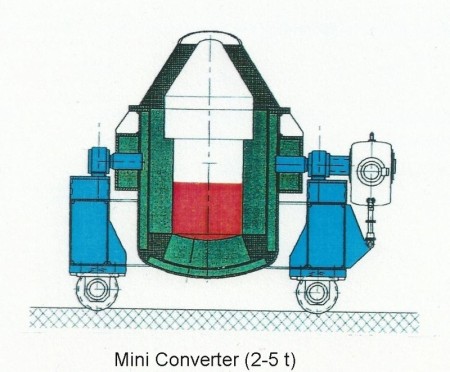

NEW GENERATION OF MINI IO-CONVERTER (TROLLEY MOUNTED)

for 2-5 t Capacity

for Steel Foundries and special alloys

by Direct Tapping from Induction Furnace

or other Melting-unit to IO-Converter

ADVANTAGES:

- § Flexible Process

- § Easy Handling and less Maintenance

- § Better Quality

- § Higher Productivity

- § Low Investment Cost

- § Improved Mechanical Properties

- § Payback in less than one year

- § Reduction in Production Cost of more than 30%